Anti-Drag Ring Cowling

Back in July, 2023, we published a report describing how Pioneer Aero had trial-fitted the SBD's "anti-drag ring cowling" to the Banshee-based ex-MGM wind machine. Perhaps better known to most of us simply as an engine cowling, this complex, three-piece subassembly is now exceedingly rare - in any condition. Indeed, the museum is very lucky to have a complete, if somewhat 'well-loved' example to work from. Each of the ring cowl's three segments (lefthand, righthand and upper) has numerous, though not insurmountable issues to rectify. This post describes the work involved with repairing the upper segment.

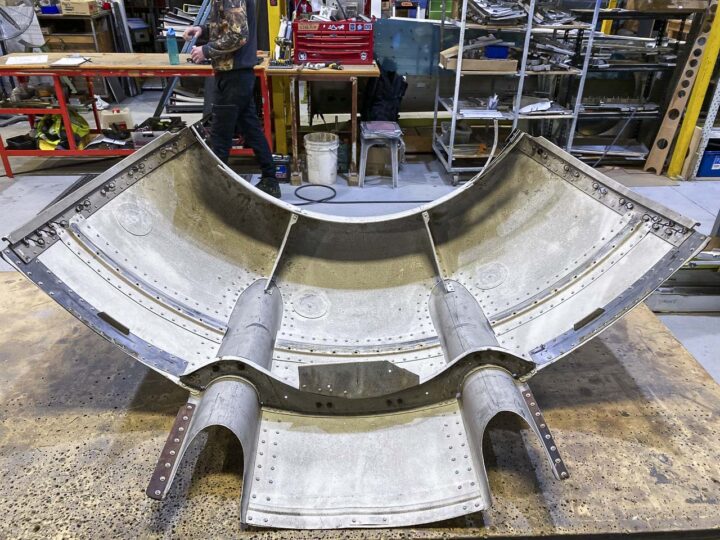

Engine Cowl Restoration: Upper Segment

As described by Pioneer Aero's Stephen Fox: "Upon disassembly and inspection of the cowl, it showed signs of reasonable fatigue with minor corrosion, but it was an excellent starting point. Everything was completely stripped back and vapor-blasted to remove the surface corrosion. The dimples have been reset to make everything nest nicely again. All edges have been dressed smooth to reduce the chance of cracking. All dents have been plannished. Some frames have been replaced due to cracking beyond repair limits. Everything has been primed and assembled, with this top cowl nearing completion."

An interior view of the cowl ring's upper segment prior to restoration commencement. (photo Via Pioneer Aero Ltd.)

A topside view of the same component. Note the two stainless steel troughs; these are the channels through which the nose-mounted .50" caliber machine guns can fire. (photo Via Pioneer Aero Ltd.)

A close-up view of a crack in one of the stainless steel gun troughs. After drilling out the rivets mounting this component to the cowl, Pioneer Aero's technicians were able to repaired the crack with a simple weld. (photo Via Pioneer Aero Ltd.)

A view of the cowl after Pioneer's technicians had drilled off the gun troughs. (photo Via Pioneer Aero Ltd.)

A close up view of a rib inside the cowl. Note that the end of the rib is missing, and has been rather crudely 'field repaired' with new material. This repair would have occurred during the aircraft's military service. (photo Via Pioneer Aero Ltd.)

Another view of the 'field repair' depicted in the previous image, but after the attached component (a gun trough) had been drilled off. (photo Via Pioneer Aero Ltd.)

Another of the panel's interior ribs showing signs of a crude field repair - note the angled section riveting the rib to the cowl skin towards image right. (photo Via Pioneer Aero Ltd.)

A view of the damaged components, and their newly-manufactured replacements. (photo Via Pioneer Aero Ltd.)