Fin Reassembly Continues:

SBD Update No.29 from February described Pioneer Aero engineer William Lowen's efforts rebuilding the aircraft's tail fin. Using refurbished parts he had salvaged from both B-22 (BuNo.36175) and an as yet unidentified donor airframe, Lowen had begun reassembling the SBD's vertical stabilizer; a fair number of parts also required refabricating.

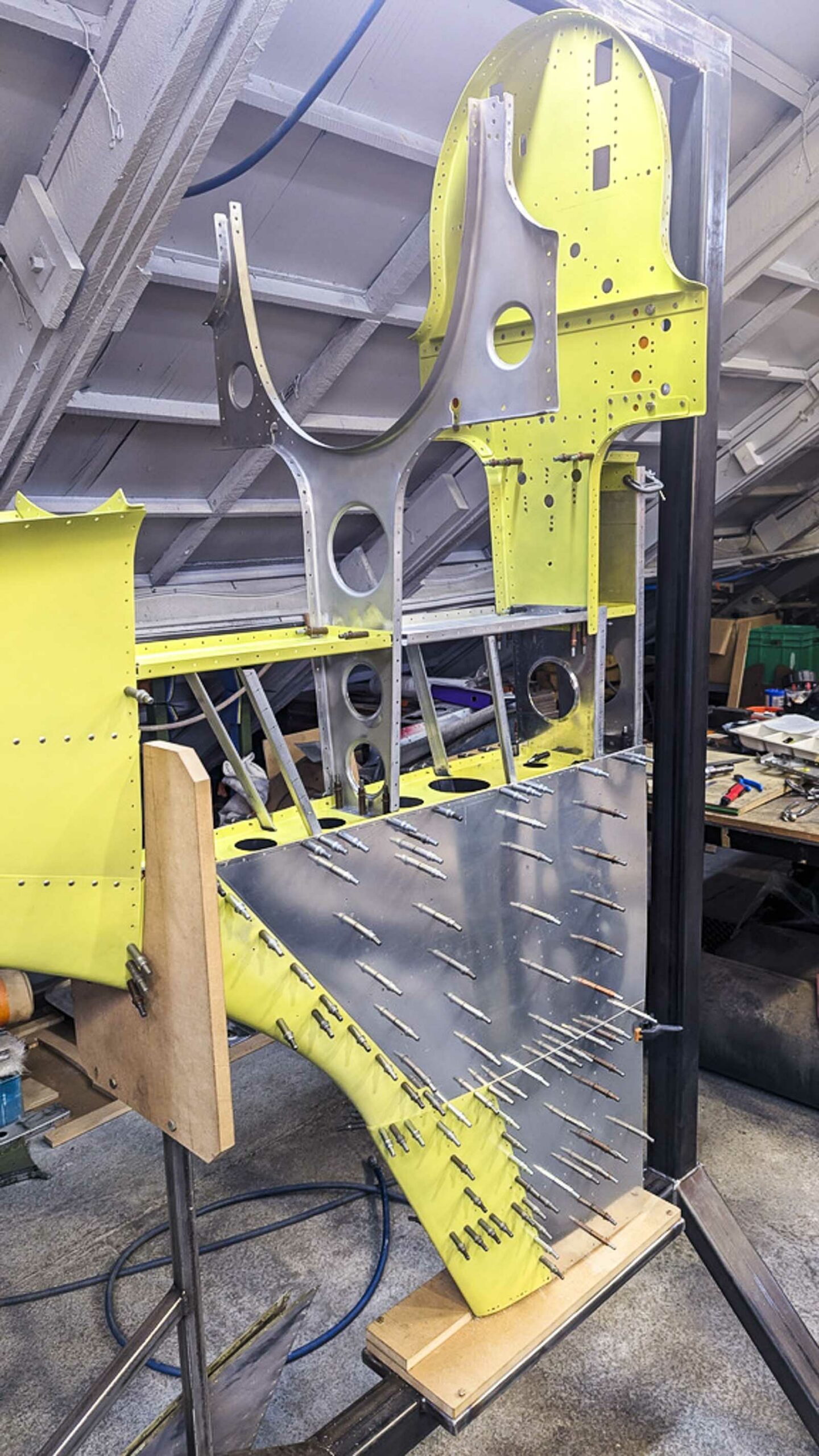

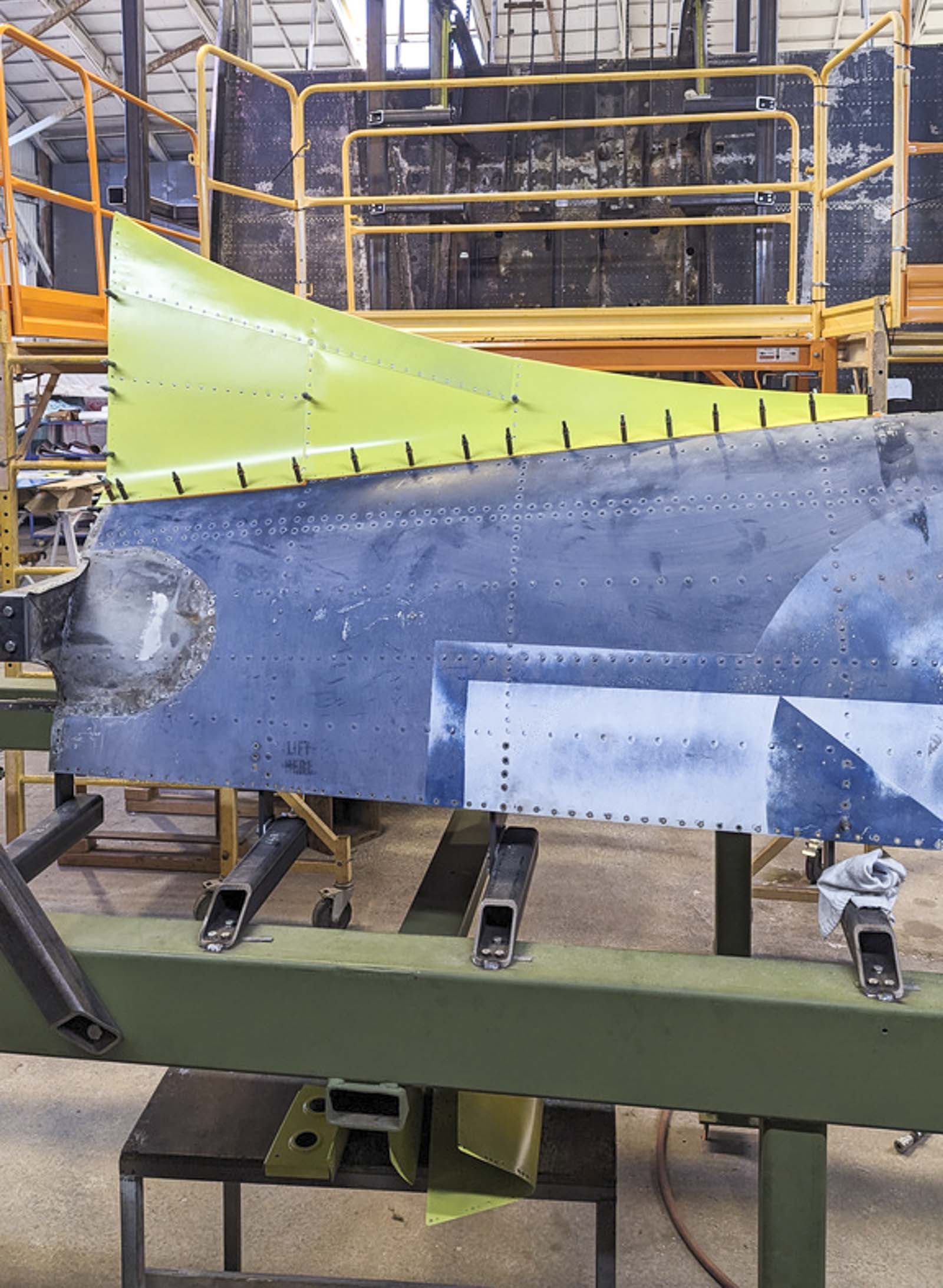

Lowen has made great progress with this project in the interim. He began by riveting the components from the fin's forward section together and trial-fitting the subassembly to B-22's fuselage with clecos to ensure everything lined up correctly, as shown in the leading, and lower two images.

Another view of the vertical stabilizer's forward section trial-fitted to B-22's upper rear fuselage to check alignment. (image via Pioneer Aero Ltd.)

Another view of the forward fin section in place on the fuselage. Note the three gaps in the fuselage skin running along the aircraft's spine. The gap at image bottom is the rearmost part of the aft turret's machine gun stowage compartment. Immediately behind that is where the aircraft collision avoidance beacon mounts. Just beyond that is the access hatch for loading parachute flares into the aircraft. (image via Pioneer Aero Ltd.)

Assembling in the Jig:

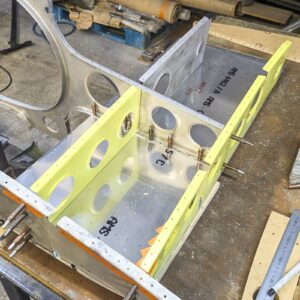

Lowen then placed the forward fin subassembly, along with other key components, in the vertical stabilizer's purpose-built jig. With these items in place, it was possible to begin lining up the interconnecting skin sections, ribs, stiffeners and bulkheads (both of original and new manufacture). Lowen then back-drilled rivet holes in the new material using the original components as a guide.

Another view of the purpose-built vertical stabilizer jig with parts assembly in progress. The lower section of Frame #17 is seen in the foreground (image via Pioneer Aero Ltd.)

A closeup featuring the lower section of Frame #17 mounted in the vertical stabilizer's reassembly jig. Note that numerous stiffeners and doubler plates are now riveted to this component. (image via Pioneer Aero Ltd.)

A new skin, and its associated stiffeners being trial-fitted in the vertical stabilizer assembly jig. Note that the rivet holes in the skin were back-drilled against an original skin section retrieved from B-22. (image via Pioneer Aero Ltd.)

Another view of the newly-manufactured skin section trial-fitted against the other vertical stabilizer components in the reassembly jig. (image via Pioneer Aero Ltd.)

Small Parts:

In addition to the reassembly work, Lowen has continued refurbishing and refabricating numerous smaller parts for the SBD's fin. This has included the restoration of four control cable pulley mounts and two cable guides associated with the aircraft's 'tail feathers'. Each of these came from the donor fin, as the examples on B-22 had irredeemable corrosion issues.

A good number of angled aluminum tabs for attaching stringers to the ribs where they intersect were also salvaged from the two tail units. The majority of these items proved reusable and they have now been stripped, inspected, fettled and primed.

Fully refurbished cable guides from the donor fin ready for reinstalling on the Museum's SBD. (image via Pioneer Aero Ltd.)

Replacement brackets for the tailwheel locking mechanism. The phosphor-bronze bushing visible in each part will ensure that the pulley which mounts between these two subassemblies will rotate freely. (image via Pioneer Aero Ltd.)

An image depicting numerous original tab angles for connecting stringers and ribs together in the SBD’s tail fin. The majority of those seen here are reusable. They are positioned with tags attached to confirm their serviceability and to also ensure that none are missing. Since this image was taken, these parts have been media-blasted, inspected and repainted with primer. (image via Pioneer Aero Ltd.)

Getting Close:

As Lowen stated: "The new skins were a good opportunity to integrate the donor parts with the original B-22 internal parts, as the holes through the skins were all drilled free hand at the factory and differ slightly from aircraft to aircraft."

The trial-fitting process continues. Once that is completed, the tail fin will undergo partial disassembly so that unpainted parts can receive a coat of primer. Final riveting will likely start soon after!