Skin Panel Disassembly:

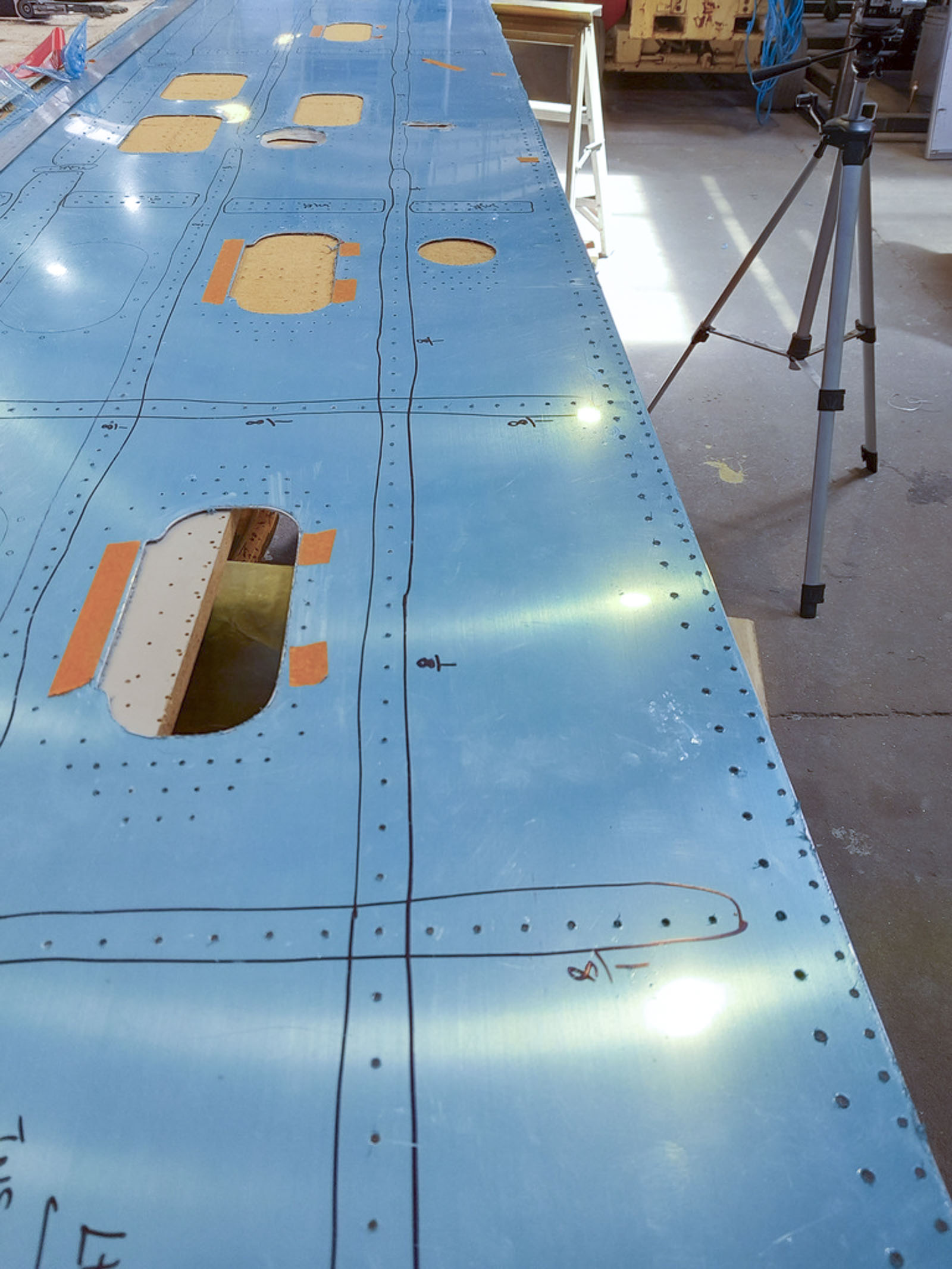

In a recent update, we described how Pioneer Aero’s restoration team removed the lower aft skin panel from the SBD’s wing center section. This is the large sheetmetal subassembly (part #5090536) which spans the entire wing center section running from Web #3 to the trailing edge bulkhead at Web #5.

In the weeks subsequent to the panel assembly's removal from the airframe, Craig Cunha and Mark Lamborn separated it into its component parts, assessing each item for its future airworthiness potential. Sadly, almost everything from the primary skin section to the access hole skin doublers, the pulley brackets, and fairing mounts was too corroded for reuse. Thankfully, they did make excellent templates for fashioning replacement parts from though.

These are some of the remanufactured doublers which stiffen the skin around each of the access holes in lower wing panel subassembly #5090536. Each of the cutouts and rivet holes has been transferred directly from the original skin, ensuring they will line up properly during reassembly. These parts, painted in primer, now await installation on the replacement skin. (photo via Pioneer Aero Ltd.)

A view of the mounting brackets for the bomb rack fairing prior to disassembly. Sadly each of these parts was too corroded for reuse, but they did prove useful templates for the manufacture of replacement parts. (photo via Pioneer Aero Ltd.)

Two original mounting brackets (right) for the bomb rack fairing and their replacements (left). The original brackets were too corroded and cracked for repair. (photo via Pioneer Aero Ltd.)

One of the pulley mounting brackets prior to its removal from lower wing subassembly #5090536. Corrosion is evident around the bolt holding the pulley in place - issues which each of these parts suffered from. (photo via Pioneer Aero Ltd.)

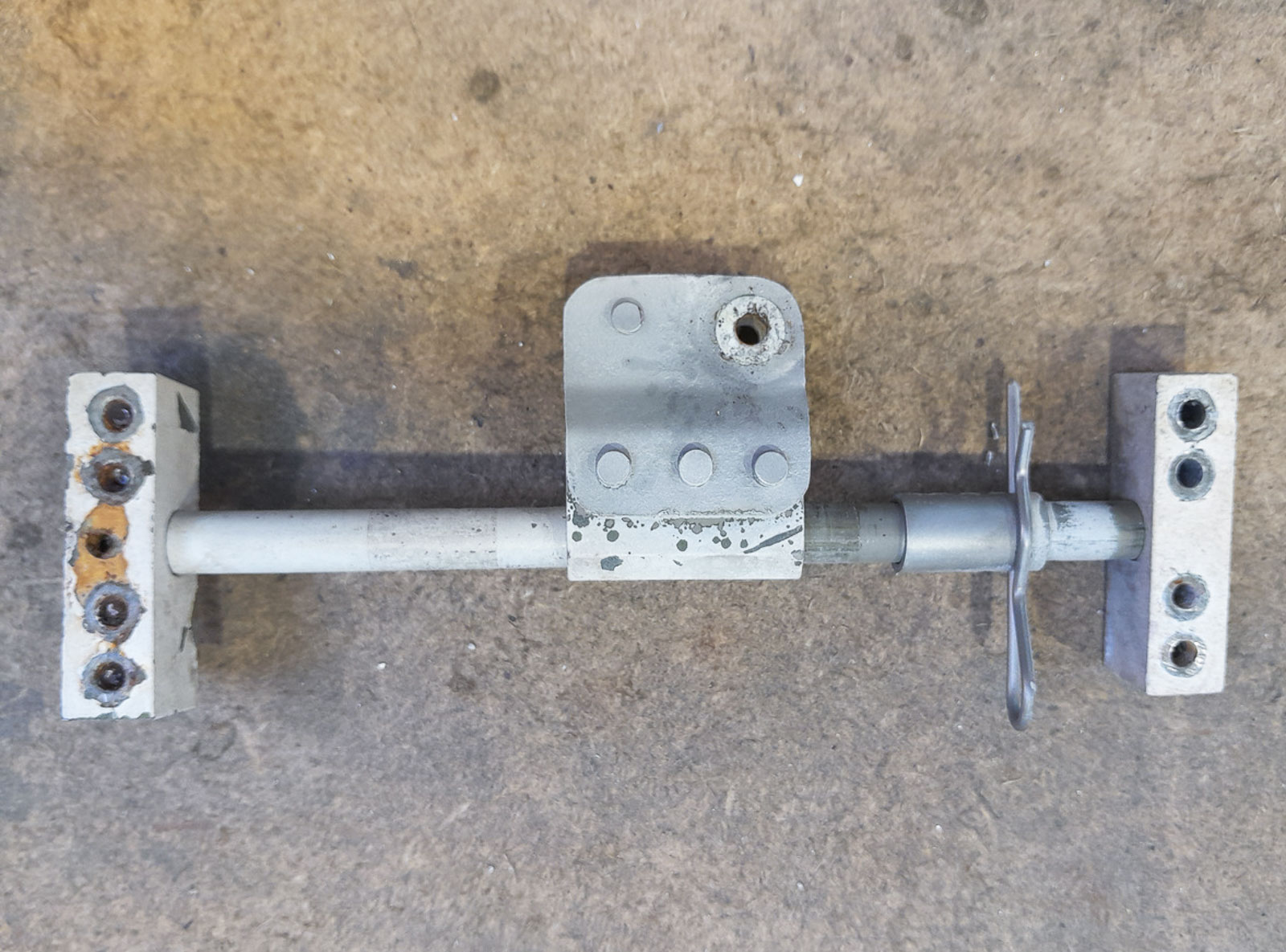

One of the pulley mounting brackets (unpainted) from lower wing subassembly #5090536 along with its replacement. The original component, while it looks in good condition, had areas of substantial corrosion which prevented its reuse. The replacement parts, painted in primer, only await the installation of their joining spacers before they are ready for riveting to the new skin panel. (photo via Pioneer Aero Ltd.)

Bomb Mount Fairing Repairs:

Despite the difficult news, several important parts were rebuildable. These included the center bomb rack fairing and the adjustable pulley mount. The team bead-blasted these components to clean away any dirt, paint and minor surface corrosion. They then repaired and repainted them, as the images below attest.

This is a closeup view of the inner face of the aft center bomb rack fairing showing an area of corrosion which has eaten completely through the aluminum beside the main fastener hole. Repairs will involve removing the affected material, adding a doubler to the inner face and then replacing the removed material with an insert. (photo via Pioneer Aero Ltd.)

A view of the repairs underway to the damage shown in the previous image. A doubler has been fashioned for the part’s inner face to provide additional strength for the repair. The doubler is seen here clecoed temporarily in place. (photo via Pioneer Aero Ltd.)

The opposite view of the repairs shown in the previous image. Note that the replacement plug for the removed section of aluminum is also clecoed here in place. All that remains is to primer paint these parts and then rivet them into the structure. (photo via Pioneer Aero Ltd.)

This is another part of the center bomb rack fairing with restorable corrosion issues. Shown here we can see that a section of the fairing has been cut out and replaced, with a doubler clecoed in place behind it. These parts will soon be fastened together with countersunk rivets to preserve the fairing’s original external profile. (photo via Pioneer Aero Ltd.)

SBD Smoke System:

The SBD featured a system for generating smoke screens to help shield friendly forces from view. The center bomb rack held the tank of smoke-producing chemicals, plumbed to a CO2 tank in the gunner’s cockpit, which contained the controls for operating the system. The adjustable pulley mount (seen below) was a part of this system, mounted to lower wing subassembly #5090536. Most of its components are in restorable condition.