Skin Panel Removal Process:

To remove one of the major skin panel assemblies from the SBD's lower wing center section, the restoration team at Pioneer Aero Ltd. first has to detach any components overlapping adjacent panels. They first employed this procedure in December 2023 when removing the skin panel assembly straddling Spar Web Nos. 3 and 5.

The team recently repeated this same process during the extraction of the skin panel assembly between Spar Web Nos.2 and 3. With the intersecting components removed, the restoration team could then de-rivet the panel (Douglas Part #5093218) from the airframe. After removing this panel from the airframe, the team then detached the internal components beneath it.

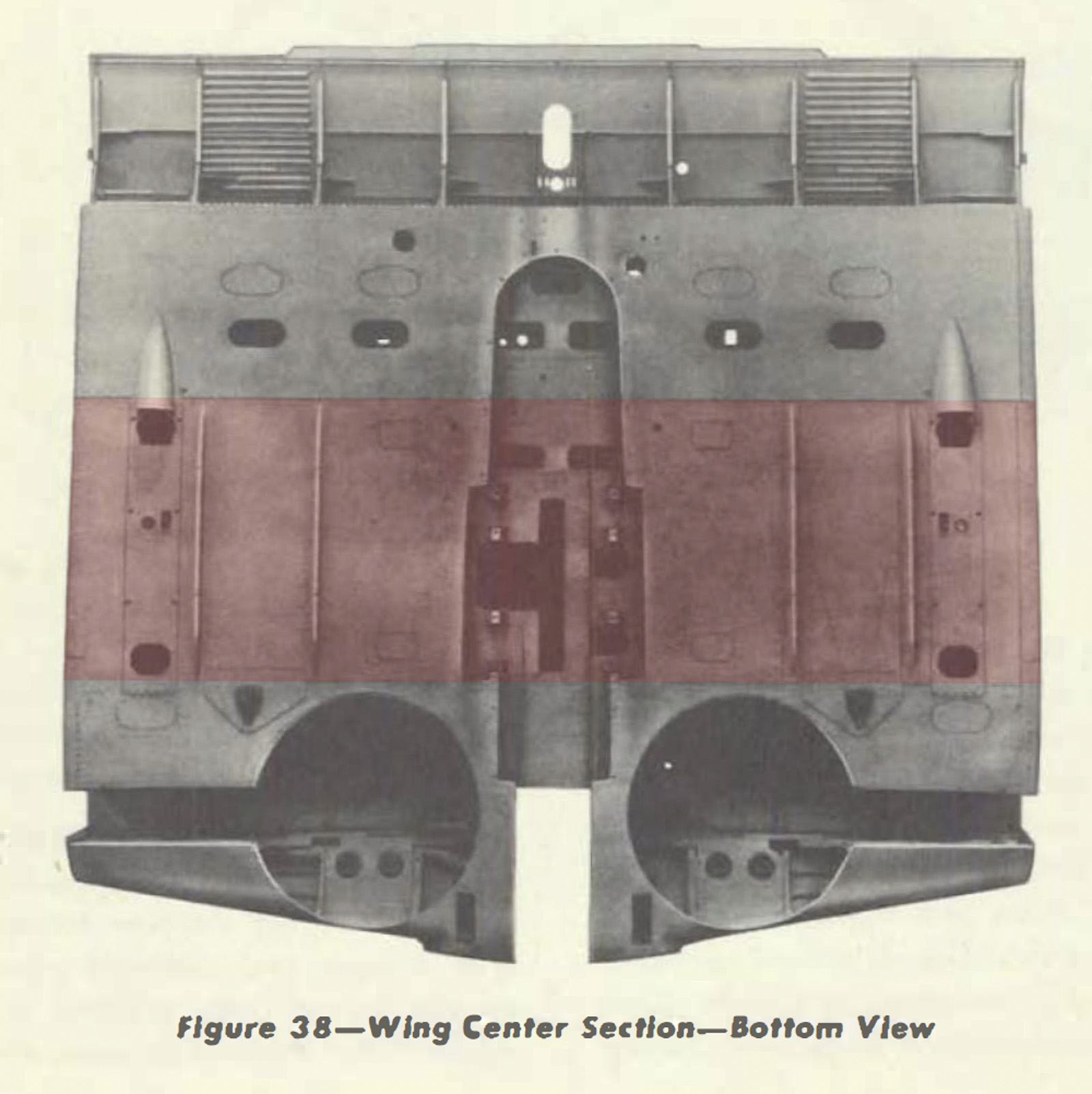

A close up view showing the lower side of the wing center section prior to removal of the skin panel between Spar Web Nos.2 and 3. Spar Web No.3 is partially exposed here, sitting at the top edge. The righthand side of the center section bomb fairing is the most prominent feature in the image, running vertically through it. It has clearly received considerable impact damage and needs replacing. Note the stencils either side of the hole whireading “WING TANK VENT”. The hole is actually the outlet for a pipe leading into the forward bulkhead in the gunner's cockpit where the venting system for the fuel tanks is located. Venting was necessary for the fuel tanks to function properly. It also prevented excess gaseous pressure building up in the tanks during warmer weather. (image via Pioneer Aero Ltd.)

Another close up view showing the lower side of the wing center section prior to removal of the skin panel between Spar Web Nos.2 and 3. At the lefthand edge of the image is the attach angle which the lefthand outer wing panel bolts onto. The large rusty hook at the center right edge of the image is where the bridle attaches during catapult launches. There are several bolts attaching this fitting to the aircraft, with the top pair connected directly to Spar Web No.2, lying beneath the pentagonal load-spreading doubler and center section skin. The fuel transfer valve cover (already removed) and one of the external ribs are visible running vertically from top center. (image via Pioneer Aero Ltd.)

Skin Replication:

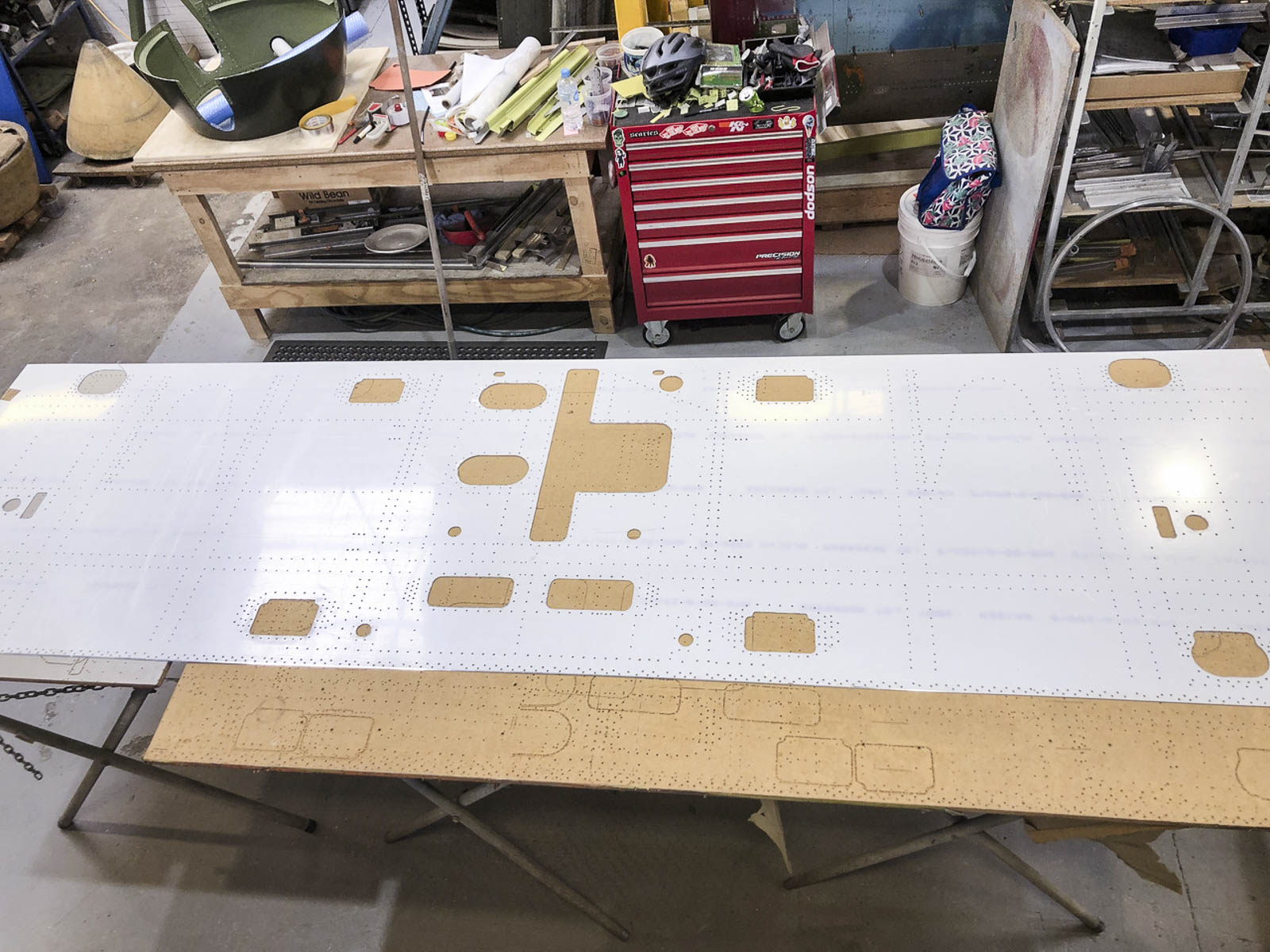

The restoration team then disassembled the skin panel into its component parts. The largest of these items, the skin itself (#5093218-34), sadly suffered from too much impact damage and corrosion to reuse. Even so, the skin was sufficiently intact to serve as a template for manufacturing its replacement. Pioneer Aero's Mark Lamborn described how the restoration team effected this effort, stating: "The next step was to lay the removed skin as flat as possible onto a new sheet of aluminum. Once these two sheets were held together firmly, I drilled through most of the original rivet holes, excluding any which were too distorted or not sitting flat."

The team essentially traced out the hole patterns from the original skin onto its replacement. Any hole locations which could not be replicated in this manner will be ascertained once the new skin is trial-fitted to the wing center section structure.

Once Mark finished back-drilling the new skin, he then traced the original component's outline and access portal apertures onto the new material (using the manufacturing drawings to confirm any missing/compromised details). He then trimmed the new material to its appropriate shape, and cut out the demarcated access holes as well.

Parts Evaluation:

In addition to the skin section remanufacture, Mark went through the process of evaluating the potential serviceability of the ancillary components removed from panel #5093218. While several parts were too damaged to sufficiently repair, a good number were overall excellent condition, and will undergo refurbishment in due course.