Upper Cowl Progress:

In October 2023, we described how Pioneer Aero had begun restoring the SBD's engine cowling - more formally referred to in the aircraft's Erection & Maintenance Manual as the "Anti-drag Ring Cowling." There are three, detachable segments in this assembly, the upper, lower left and lower right. The upper segment features troughs through which the two nose-mounted machine guns can fire. Stephen Fox, Pioneer's engineer responsible for refurbishing the nose cowls had already made great progress with the upper section in the last update. Stephen was able to repair this 'well-loved' subassembly, reusing all of its major components and most of the smaller elements too. The panel is now almost completely restored, as the following images will reveal.

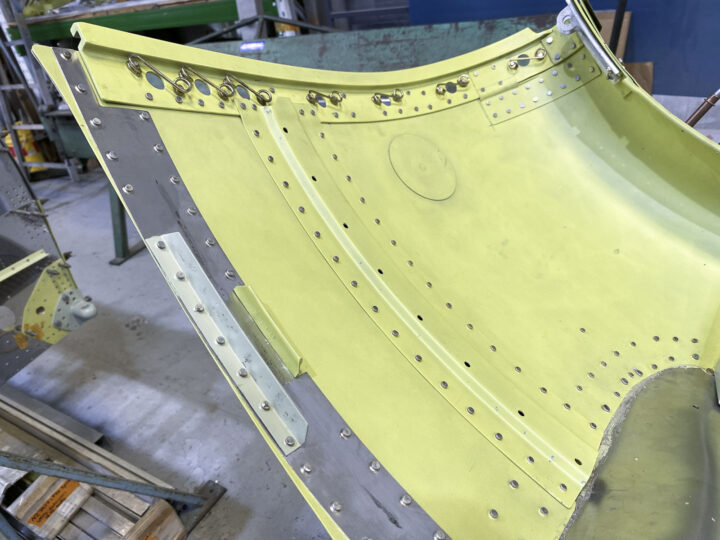

Here is a view of the other side of the upper engine cowling segment. This has also had its stainless anti-chafing strip and Dzus springs installed. Note that a skin splice has also been riveted in place near the leading edge. This repair resulted from some corrosion damage and a small crack to the original material in that area. (Image via Pioneer Aero Ltd.)

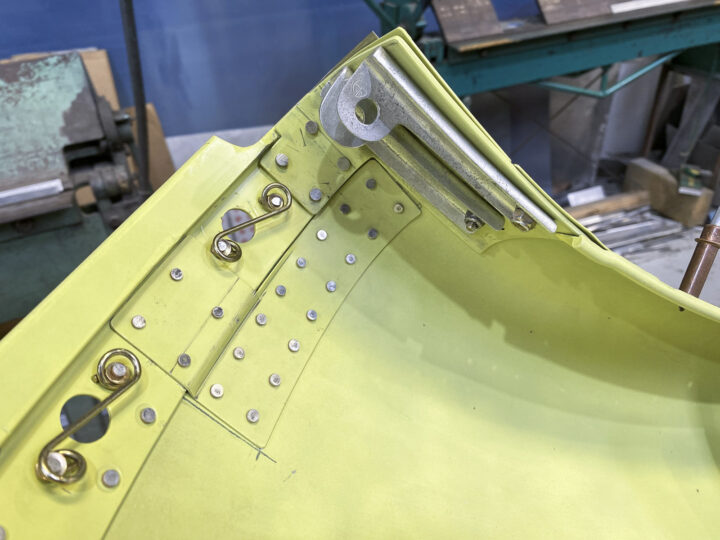

An interior rightside view of the upper engine cowling segment with a clear view of the newly-installed Dzus springs. (Image via Pioneer Aero Ltd.)

Another interior, rightside view of the upper engine cowling segment. Note the circular skin stiffener near the center of the image. This is actually spot welded in place and part of the components original design, rather than a skin splice repair. (Image via Pioneer Aero Ltd.)

A close up view showing the repair to the leading edge of the upper cowling segment. Note the skin splice which has been riveted in against a backing plate. Note also the steel latch mechanism at the leading edge. This is an original component, cleaned and cadmium plated as originally designed. (Image via Pioneer Aero Ltd.)

Lower Left Cowl Segment:

Stephen Fox has also worked wonders in restoring the lower left segment of the SBD's engine cowl as well. As with the upper section, all of the major elements were reusable, as were most of the smaller pieces. A few small areas required skin grafts to repair damage, but Fox was able to splice these into the structure almost seamlessly. Fox was also able to salvage each of the adjustable steel latches which link the left and right lower cowl sections together. After media-blasting, these latches received a new layer of cadmium plating, returning them to virtually as-new condition. With the left lower cowl now almost complete, Fox will soon put the lower right cowl through the same process.

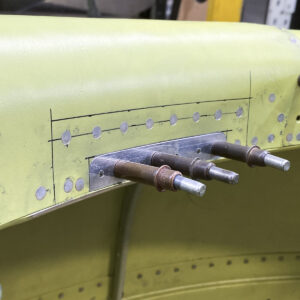

Another closeup view of a skin repair to the leading edge of the lefthand lower cowl section. The large mounting holes along the edge will soon be fitted with Dzus fasteners. (Image via Pioneer Aero Ltd.)